Ladderback chairs had been on my mind for a while. My interest was sparked by Jenny Alexander’s classic Make a Chair from a Tree, and more recently by Andrew Glenn’s Backwoods Chairmakers. Ladderbacks are post and rung chairs; four vertical posts are held in place by a series of horizontal rungs. The rungs support the seat which is typically woven from bark, cord, or fabric. Ladderbacks are a traditional chair made mainly with hand tools. They are made from straight green wood (typically oak or hickory) which is split out (rived) from the log. The resulting chair parts have wood fibres running their full length, giving them maximum strength. Straight grain and green wood is also conducive to steam bending, which is used to beautiful effect on some ladderbacks, like the classic “ Jennie Chair.” I’ve been looking for suitable wood for the last couple of years, so far with no luck.

Late in 2024 we visited good friends LJ and Cameron on Gabriola Island. A fall storm recently brought down a bigleaf maple tree on their property. I was initially wondering if there were any curved branches lying around, the kind that would form the arm of a welsh chair. But things had been cleaned up and I could not find anything suitable. However there was a decent sized log on the ground. It was a bit over a foot in diameter and about six feet long. I wondered if this could be used for making ladderback chairs. So there we were on a December Gabriola morning, staring at this wet maple log. Cameron said I could have it if I wanted it. Though there was no way the two of us could lift it, let alone fit it into the trusty old jetta. But using an axe, a sledge, and a maul we were able to split the log lengthwise in half and then into quarters. The quartered pieces could then be cut in half and those shorter pieces would fit in the back of the car. And that’s how those pieces arrived in our back yard, where I began breaking those quarters into chair-sized pieces using a froe, mallet, sledge and gluts.

As I started butchering that log a couple of things became apparent. The wood had some beautiful curly figure. Not uncommon for big leaf maple, but always a delight to discover. However the wood was not as straight-grained as I had hoped. There were lots of small branches running through the log, and grain wandered back and forth following those branches. This made it challenging to find long straight-grained wood, and to split the wood out into smaller pieces. I eventually resorted to the bandsaw for some of the finer splitting. And I began to see that I would not have beautiful clear straight material to work with. I was now aiming at chairs with a more -ahem- rustic character. And despite occasionally using the bandsaw, most of the shaping work involved hand tools, particularly the drawknife and spokeshave. My hands and forearms were getting a real workout.

Maple is a terrible for bending. But I naively hoped that if I soaked the already green wood I might be able to coax it into the gentle curves that I needed. I did manage to bend the thinner back rails, but when I tried to bend the thicker back posts I broke most of them. I ran out of wood and patience with only three partially successful bends, none of which would work for this chair. So my first ladderback would have a straight back. Not uncommon, but not what I was hoping for.

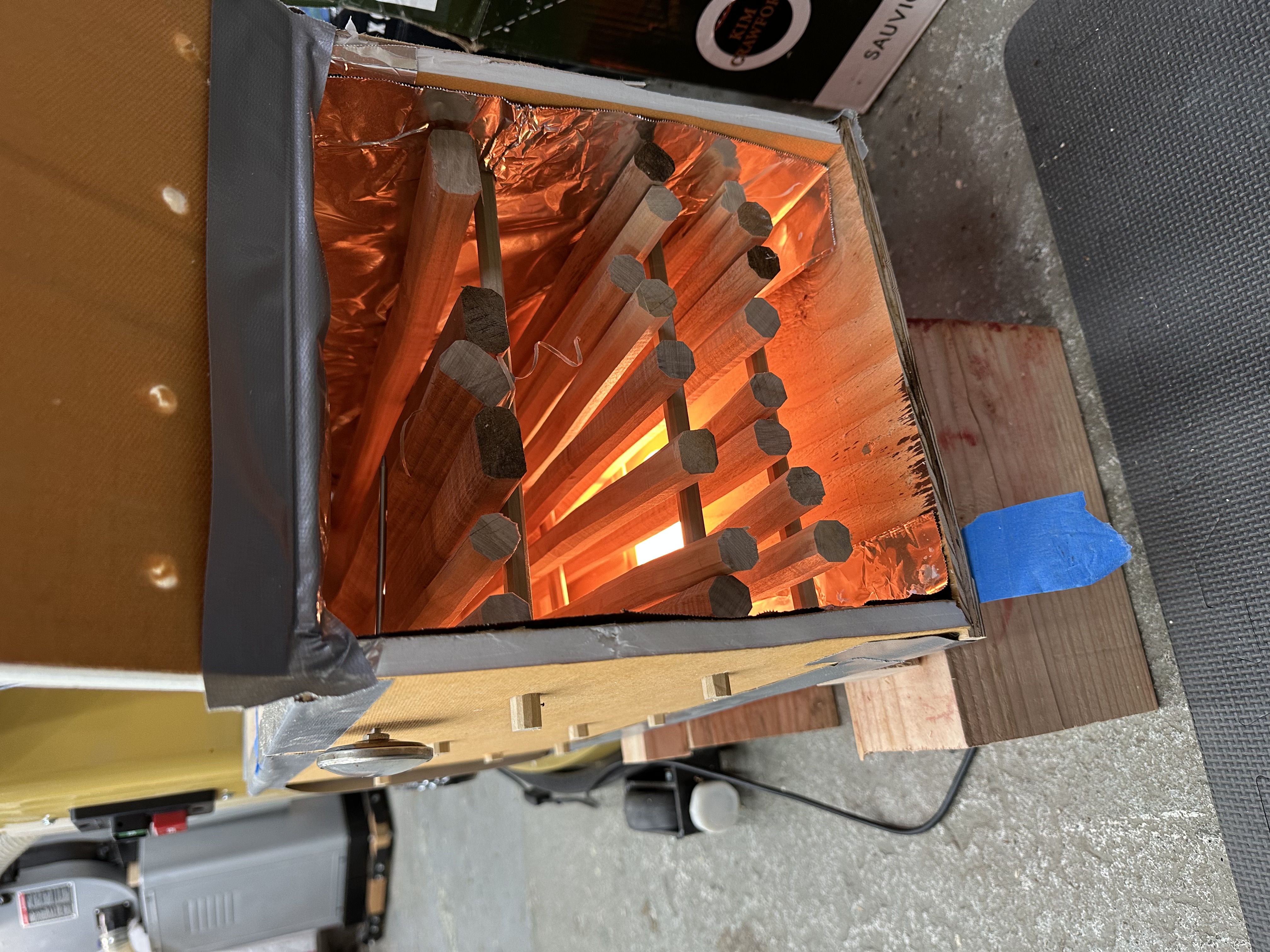

The ladderback is a light and efficient chair. The joint between post and rung holds it all together and a typical chair has twenty or more of these joints. There’s a trick that helps keep everything tightly locked. The rungs are dried in a small kiln before tenons are cut in the ends. The mortises are cut into the green wood of the posts. So once the parts are assembled and the wet posts shrink slightly as they dry out and the dry rungs expand slightly as they return to ambient humidity. (I’ve been told that this method works even without glue, but I used glue for added insurance). Before I worked on posts and back rails I roughed out rungs and placed them in a home-made kiln, an insulated box heated with a light bulb.

Assembly turned out to be easier than expected. With all the curves and wobbles in the posts and rungs I was afraid that the pieces would not fit together, but the wood had enough flex that it could be bent into place when parts were not perfectly aligned. And nothing was perfectly aligned. The joints were very tight so it took a bit of effort with clamps and hammer to get everything seated properly. The assembled chair was a collection of subtle and not-so-subtle organic curves and wobbles, with few of the curves where I actually wanted them. Turns out that an Appalachian ladderback chair in bigleaf maple was possible, even if it might not be the smartest idea.

After a final cleanup and a coat of Osmo it was time to make the seat. While hickory bark is traditional material, danish paper cord was my only practical option. This was my first attempt at a woven seat and the results are a bit wonky, so nicely matched to the rest of the chair.

Bigleaf Maple, Danish paper cord, Osmo wax oil